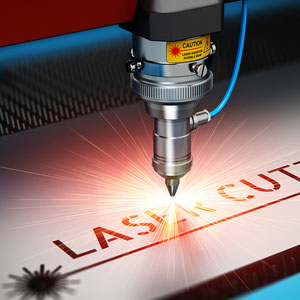

Laser Cutting

Laser cutting offers significant benefits over many traditional manufacturing operations, such as plasma cutting, photo etching, turret punching, CNC, EDM and water jet cutting among others.

Laser technologies helps to cutting aluminum, brass, carbon steel, copper, nickel, stainless steel, silver, super alloys, tantalum, titanium, tungsten, platinum, plastics, rubber, ceramics etc.,

Advantages of Laser Cutting

Cutting narrow kerf widths, which promotes efficient part nesting, yielding better sheet utilization and material savings

Fast , Reliable and Accurately repeatable

Reduced time for set-up with the ability to react and adapt quickly to changing production needs that are market or quantity driven

Efficient processing, as multiple jobs or parts can be nested and cut in a single program

No secondary clean up process required for most materials, and is usually ready for immediate shipment

Following Ultra High Pure Grade (5.0 , 5.5 & 6.0 Grade) Gases, helps to Accurate Jobs & End Product as per desired level.

Ultra High Pure Helium :: Purity Level: 99.9999(%)

Ultra High Pure Nitrogen :: Purity Level: 99.9999(%)

High Pure Oxygen :: Purity Level: 99.999(%)

High Pure Carbon Di-oxide(Co2) :: Purity Level: 99.999(%)

Pre mixed laser gases :: various type of Ratio available

| Laser gas:pre-mixed gas for laser cutting. | Helium | Nitrogen | Co2 |

|---|---|---|---|

| Laser Gas Ratio 1 | 74.9% | 23.4% | 1.7% |

| Laser Gas Ratio 2 | 61.0% | 34.0% | 5.0% |

| Laser Gas Ratio 3 | 40.0% | 55.0% | 5.0% |

Based on customer machine requirements, gas mixture ratio will be prepared & supplied with high quality as per standards.

Suitable for:

Triumph laser

Amada laser

Mazak laser etc., All laser machine requirements...

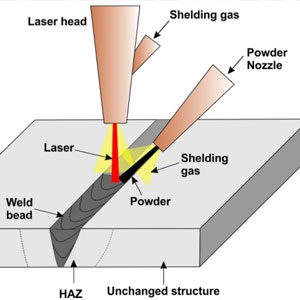

Laser Welding

Laser welding is a proven joining method for a variety of today’s metals and metal alloys. Laser welding offer a unique alternative to TIG welding, EB welding, resistance welding, brazing, silver soldering and adhesive bonding methods.

Lasers can successfully weld various grades of carbon steels, nickel alloys, stainless steels, titanium alloys, super alloys and more. High production volumes associated with fully automated or semi-automated tooling applications.

Metal Sheet & Component Welding, Precision Metal, Tube Welding.

Carbon Steels, Nickel Alloys, Stainless Steels, Titanium Alloys, Super Alloys.

Advantages of Laser Welding

Less distortion on work pieces because metal is fused within a very small area at high speeds and welds that are consistent and reliable

Higher production rates, thus saving you money

Little or no joint preparation required for this type of welding, saving additional time and money

We offer narrow, precision weld beads with excellent cosmetic appearance, to a high degree of accuracy

Laser welding allows for joining dissimilar metals with no filler metal

Industries:

Aerospace

Automotive

Electronics

Energy

Defense

Nuclear

Medical

File Format:

AutoCAD (DWG, DXF)